Request a callback

Please give us your contact details and we will call you back

By clicking the Submit button I confirm my consent to the privacy Policy and agree to the processing of my personal data

Construction and Architecture

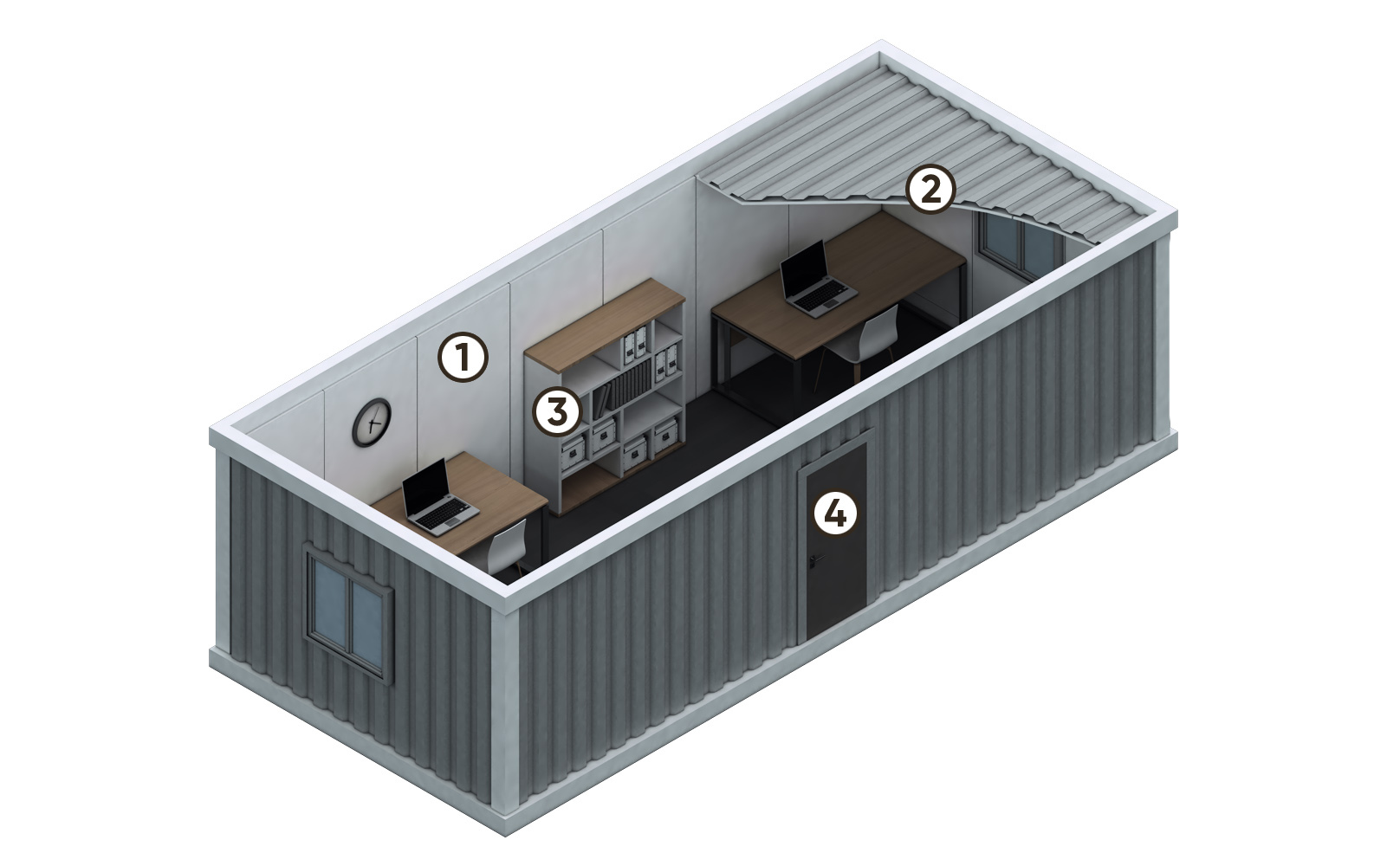

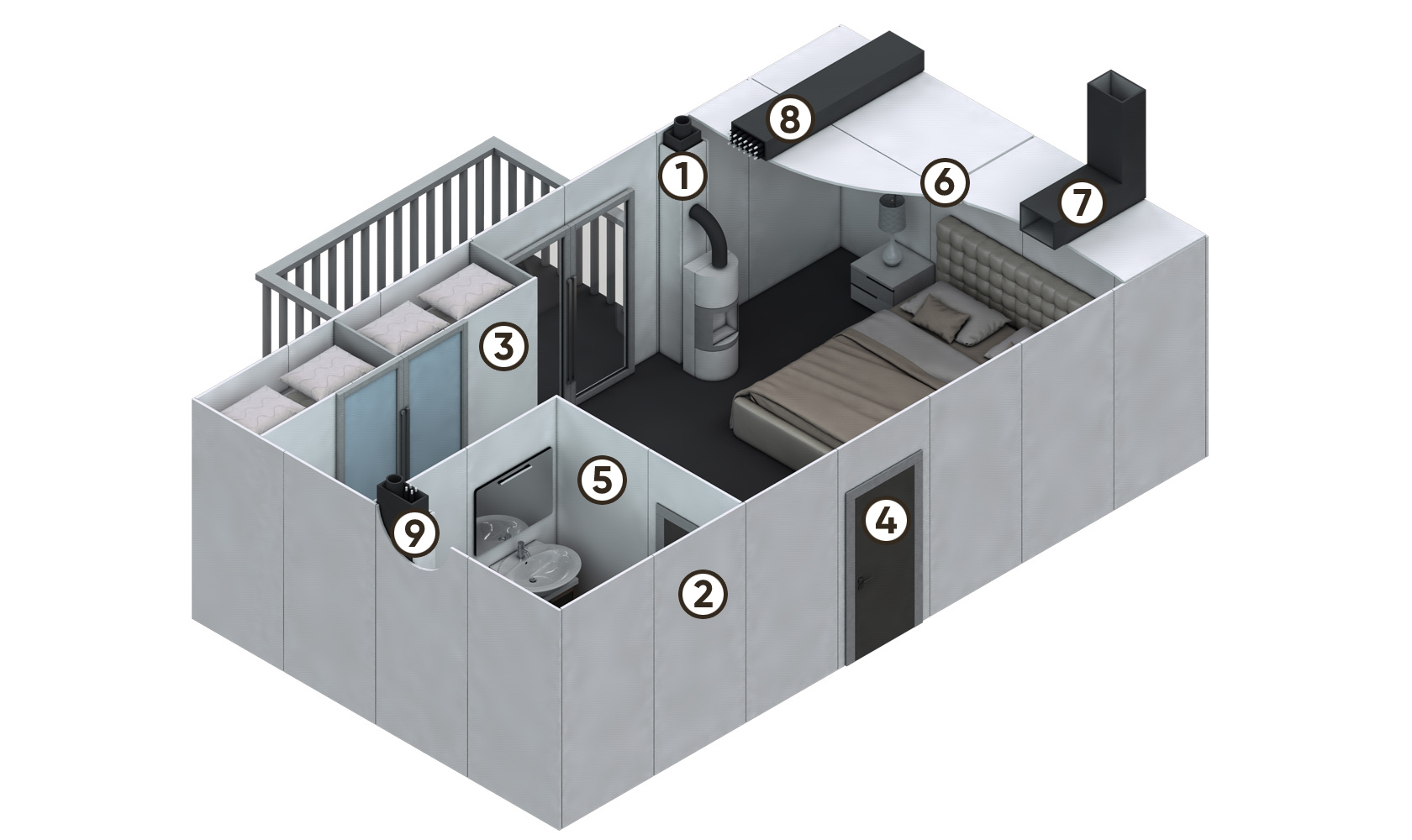

1. FIREPLACES: FirePan / FireCore

2. WALLS: FirePan / SeaPan

3. INTERIOR ELEMENT: FirePan / SeaPan

4. DOORS, GATES, HATCHES: FireCore / LifeRock

5. PARTITIONS: FirePan / SeaPan

6. CEILINGS: FirePan / FireCore / LifeRock / SeaPan

7. VENTILATION: FirePan / FireCore / SeaPan

8. CABLE DUCTS: FirePan / FireCore / SeaPan

9. COMMUNICATION DUCTS: FirePan / FireCore / SeaPan

2. WALLS: FirePan / SeaPan

3. INTERIOR ELEMENT: FirePan / SeaPan

4. DOORS, GATES, HATCHES: FireCore / LifeRock

5. PARTITIONS: FirePan / SeaPan

6. CEILINGS: FirePan / FireCore / LifeRock / SeaPan

7. VENTILATION: FirePan / FireCore / SeaPan

8. CABLE DUCTS: FirePan / FireCore / SeaPan

9. COMMUNICATION DUCTS: FirePan / FireCore / SeaPan

Rapidly developing, modern architecture is not only expanding the range of applied technical solutions and implementing the latest trends in design, but is also designed to address a number of problems associated with the progressive urbanization of humanity and the globalization of economic development. Increase in density of building and number of storeys of building, growth of power saturation of inhabited and industrial premises demands additional requirements to maintenance of fire safety and creation of the maximum comfort for life activity of people on the basis of simple and economically advantageous decisions.

Rapidly developing, modern architecture is not only expanding the range of applied technical solutions and implementing the latest trends in design, but is also designed to address a number of problems associated with the progressive urbanization of humanity and the globalization of economic development. Increase in density of building and number of storeys of building, growth of power saturation of inhabited and industrial premises demands additional requirements to maintenance of fire safety and creation of the maximum comfort for life activity of people on the basis of simple and economically advantageous decisions.

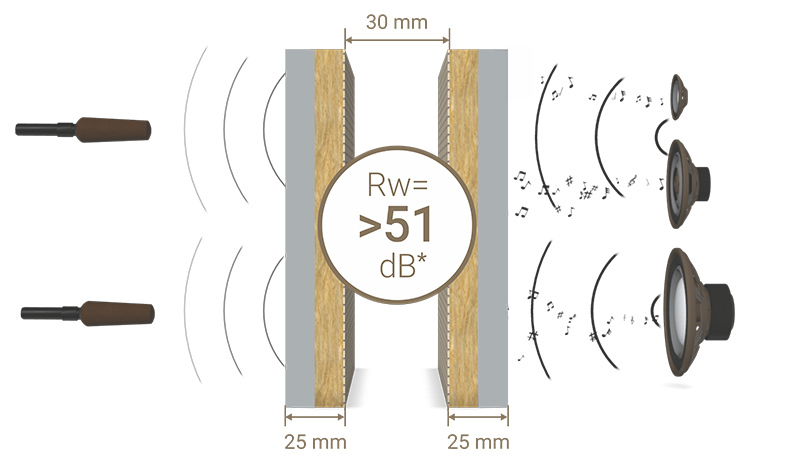

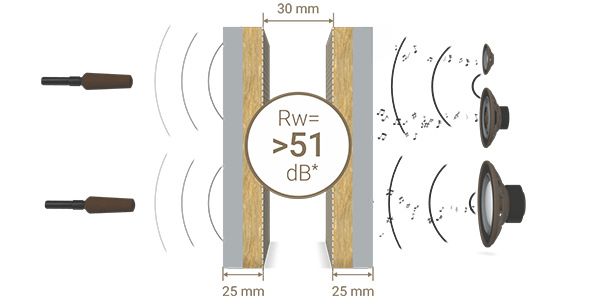

Our products are manufactured from and/or based on inorganic materials and are the vast majority of products classified as non-combustible according to DIN 4102 and/or DIN EN 13501 in category A1. Our products in their pure state, without the need for multilayer constructions, allow for constructions with a given fire resistance of 15, 30, 60 and 90 minutes. They can withstand temperatures of more than 1,100°C, are made of 100% natural materials, are non-toxic, smoke-free in case of fire, waterproof, vibration and UV resistant, ultra-lightweight (specific gravity less than 300 kg/m³) and have unique soundproofing properties (> 51 dB) with a structural thickness of less than 100 mm.

Unsere Produkte werden aus und/oder auf Basis von anorganischen Materialien hergestellt und überwiegend nach DIN 4102 und/oder DIN EN 13501 als nicht brennbare Baustoffe der Klasse A1 eingeteilt. Mit unseren Produkten lassen sich Bauten mit einer vorgegebenen Feuerbeständigkeit von 15, 30, 60 und 90 Minuten verwirklichen - und zwar ganz ohne Sandwich-Konstruktionen. Diese Produkte können Temperaturbelastungen von bis 1.100°C standhalten, werden zu 100 % aus natürlichen Materialien hergestellt, sind ungiftig, geben im Brandfall keinen Rauch ab, sind wasserdicht, schwingungsfest und UV-beständig, ultraleicht (spezifisches Gewicht unter 300 kg/m³) und verfügen über einzigartige schalldämmende Eigenschaften (> 51 dB) bei einer Trennwanddicke von unter 100 mm.

Fire-resistant, heat- and noise-proof, extremely lightweight, shape stable, easily machinable with conventional cutting tools and perfectly able to withstand mechanical loads CBG Composites GmbH products are perfectly suitable for the production of fire- and noise-proof enclosures for working machines as well as noise, heat- and fire-proof machine parts and various structures.

Fire-resistant, heat- and noise-proof, extremely lightweight, shape stable, easily machinable with conventional cutting tools and perfectly able to withstand mechanical loads CBG Composites GmbH products are perfectly suitable for the production of fire- and noise-proof enclosures for working machines as well as noise, heat- and fire-proof machine parts and various structures.

The system of coupling of panels "tongue-and-groove" developed and used by us in combination with their good mechanical and structural parameters allows to assemble the necessary constructions with the minimum effort on time and resources by use of conventional cutting tool.

Of course, in addition to the above connection of individual construction elements, our panels can also be mounted perpendicular to each other using screw connections and conventional standard fastening elements as floor, ceiling and corner elements and guide rails. In any case, we will be happy to help you choose the optimal solution.

If you do have any further questions, we are waiting for you to contact us. You will find our contact details on our website.

The system of coupling of panels "tongue-and-groove" developed and used by us in combination with their good mechanical and structural parameters allows to assemble the necessary constructions with the minimum effort on time and resources by use of conventional cutting tool.

Of course, in addition to the above connection of individual construction elements, our panels can also be mounted perpendicular to each other using screw connections and conventional standard fastening elements as floor, ceiling and corner elements and guide rails. In any case, we will be happy to help you choose the optimal solution.

If you do have any further questions, we are waiting for you to contact us. You will find our contact details on our website.

Of course, in addition to the above connection of individual construction elements, our panels can also be mounted perpendicular to each other using screw connections and conventional standard fastening elements as floor, ceiling and corner elements and guide rails. In any case, we will be happy to help you choose the optimal solution.

If you do have any further questions, we are waiting for you to contact us. You will find our contact details on our website.