Request a callback

Please give us your contact details and we will call you back

By clicking the Submit button I confirm my consent to the privacy Policy and agree to the processing of my personal data

Research & Development

CBG Composites GmbH has many years of experience in scientific developments and their implementation in practice. We have always paid particular attention to the environmentally friendly use of composite materials of natural origin, with the aim of reducing energy costs and the greenhouse effect and increasing the degree of recycling of our products. We successfully cooperate with leading research institutions in Europe and provide services for third parties in solving practical problems in our fields of work. In the past 5 years, we have obtained 7 utility model patents and more than 10 trademarks have been registered.

The focus of our work is currently the development, implementation and practical application of our solutions and technologies in the following areas:

1. Non-combustible endothermic matrices and their application in the manufacture of composite materials.

2. The use of basalt and its derivatives as a base material in innovative composite technologies.

3. Non-combustible composite materials and their application in the field of soundproofing.

4. Non-combustible ultra-light materials and their application in shipbuilding.

5. Non-combustible ultra-light materials and their application in architecture and construction.

6. Additive technologies to produce high-temperature resistant products from biosoluble ceramic fibers.

7. Phenolic free inorganic binder CBG Ceramant 07-04 for production of mineral fibre thermal insulation materials.

If you have any questions and/or are interested in cooperation with us, we look forward to hearing from you.

The focus of our work is currently the development, implementation and practical application of our solutions and technologies in the following areas:

1. Non-combustible endothermic matrices and their application in the manufacture of composite materials.

2. The use of basalt and its derivatives as a base material in innovative composite technologies.

3. Non-combustible composite materials and their application in the field of soundproofing.

4. Non-combustible ultra-light materials and their application in shipbuilding.

5. Non-combustible ultra-light materials and their application in architecture and construction.

6. Additive technologies to produce high-temperature resistant products from biosoluble ceramic fibers.

7. Phenolic free inorganic binder CBG Ceramant 07-04 for production of mineral fibre thermal insulation materials.

If you have any questions and/or are interested in cooperation with us, we look forward to hearing from you.

1. Non-combustible matrices for composites (and even endothermic!).

Composites are strong and lightweight, but where do you find matrix with good fire resistance, or non-combustible at all? Especially if you must follow the demanding DIN EN ISO 1182.

At CBG Composites GmbH we think that a truly non-combustible matrix should be made of inorganic components and we specialize in that (our non-combustibility tests are carried out according to DIN EN ISO 1182 or IMO 2010 FTP Code Part 1).

We developed, certified and currently produce a whole family of non-combustible matrices, which differ both in their properties and in their applications, such as non-combustible panels of different fire resistance classes, matrices for impregnating non-combustible materials and matrices for Increasing the fire resistance of organic materials such as wood, etc.

The products below offer a number of advantages over the traditional products on the market.

LR Cerammatrix® 01-50 is an inorganic, water-based adhesive matrix with an endothermic effect. It has high holding power, excellent adhesion and is suitable for bonding woven and non-woven materials, mineral wool, concrete, ceramics, wood and metals (except aluminum).

In addition, Cerammatrix has special components that provide an endothermic effect (chemical cooling) that prevents the passage of heat flow. The developed adhesive matrix LR Cerammatrix® 01-50 has a significant advantage that allows to reduce the weight and the thickness of a fire protection wall of the respective fire resistance class. LR Cerammatrix® 01-50 was tested in 2020 at DMT Dortmund according to FTP Code Part 1 (DIN EN ISO 1182) (Fire test report of a fire protection adhesive mass "CBG - LR Cerammatrix® 01-50" to determine non-combustibility). This matrix is certified as non-combustible material, has received the corresponding MED Module B certificate and has WIWEB approval (Bundeswehr Research Institute for Materials, Fuels and Lubricants).

Cerammatrix Carbo differs from LR Cerammatrix® 01-50 in that it contains nanoscale carbon particles that contribute to better protection against the ingress of heat flow at temperatures above 900°C. This is because above about 900 °C heat transfer in these materials occurs mostly by radiation (not convection). Cerammatrix Carbo also has good strength, excellent adhesion and endothermic effect. Cerammatrix Carbo was tested at DMT Dortmund in 2020 according to FTP Code Part 1 (DIN EN ISO 1182) and found to be non-flammable (Fire test report of a fire protection adhesive mass "CBG - Cerammatrix-Carbo" to determine non-flammability). Cerammatrix Carbo is designed for bonding woven and non-woven materials, mineral wool, concrete, ceramics, wood and metal (except aluminum).

FiberMatrix is a non-flammable, water-based ceramic filler with endothermic effect, reinforced with short basalt fibers. The reinforcing fibers make it possible to use this putty to create 3D shapes for various non-combustible interior architectural elements. It has ultrahigh strength and excellent adhesion to woven and non-woven materials, mineral wool, concrete, ceramics, wood and metal (except aluminum). The material was successfully tested for non-combustibility according to FTP Code Part 1 (DIN EN ISO 1182) in the laboratory of CBG Composites GmbH. Due to its properties, FiberMatrix makes it possible to reduce the weight of 3D products and at the same time achieve high strength.

CBG fako® - Glass Fibre Adhesive 9119xtra is a solvent-free plastic dispersion adhesive, which is characterized by high elasticity. A one-component adhesive set thixotropic in nature. CBG fako® - glass fibre adhesive No. 9119 is used for the bonding of glass fibre fabric on mineral wool in pipe and surface area, and used to manufacture a glass cloth cover on rubber products (e.g. Armaflex). The adhesive can be used on stable substrates such as plaster, plasterboard and concrete.

Certificates & test reports:

FireStop is an inorganic, water-based impregnation for wood, concrete and fiber materials that penetrates deep into the pores of concrete, wood layers and the space between fibers, increasing fire and moisture resistance. It has a fungicidal effect (against mold and fungi). The advantage is that FireStop penetrates up to 8 mm deep. The fire protection class of wood goes up after impregnation to class B1 according to DIN 4102.

In addition, FireStop has endothermic effect (provides chemical cooling when heated) and is used to impregnate the cores of non-combustible sandwich panels. The company received a German Utility Model DE 20 20 20 103 298 U1 for using FireStop to impregnate non-combustible sandwich panel cores.

The company monitors developments in this area and develops new products that meet the needs of the market and customers.

Composites are strong and lightweight, but where do you find matrix with good fire resistance, or non-combustible at all? Especially if you must follow the demanding DIN EN ISO 1182.

At CBG Composites GmbH we think that a truly non-combustible matrix should be made of inorganic components and we specialize in that (our non-combustibility tests are carried out according to DIN EN ISO 1182 or IMO 2010 FTP Code Part 1).

We developed, certified and currently produce a whole family of non-combustible matrices, which differ both in their properties and in their applications, such as non-combustible panels of different fire resistance classes, matrices for impregnating non-combustible materials and matrices for Increasing the fire resistance of organic materials such as wood, etc.

The products below offer a number of advantages over the traditional products on the market.

LR Cerammatrix® 01-50 is an inorganic, water-based adhesive matrix with an endothermic effect. It has high holding power, excellent adhesion and is suitable for bonding woven and non-woven materials, mineral wool, concrete, ceramics, wood and metals (except aluminum).

In addition, Cerammatrix has special components that provide an endothermic effect (chemical cooling) that prevents the passage of heat flow. The developed adhesive matrix LR Cerammatrix® 01-50 has a significant advantage that allows to reduce the weight and the thickness of a fire protection wall of the respective fire resistance class. LR Cerammatrix® 01-50 was tested in 2020 at DMT Dortmund according to FTP Code Part 1 (DIN EN ISO 1182) (Fire test report of a fire protection adhesive mass "CBG - LR Cerammatrix® 01-50" to determine non-combustibility). This matrix is certified as non-combustible material, has received the corresponding MED Module B certificate and has WIWEB approval (Bundeswehr Research Institute for Materials, Fuels and Lubricants).

Cerammatrix Carbo differs from LR Cerammatrix® 01-50 in that it contains nanoscale carbon particles that contribute to better protection against the ingress of heat flow at temperatures above 900°C. This is because above about 900 °C heat transfer in these materials occurs mostly by radiation (not convection). Cerammatrix Carbo also has good strength, excellent adhesion and endothermic effect. Cerammatrix Carbo was tested at DMT Dortmund in 2020 according to FTP Code Part 1 (DIN EN ISO 1182) and found to be non-flammable (Fire test report of a fire protection adhesive mass "CBG - Cerammatrix-Carbo" to determine non-flammability). Cerammatrix Carbo is designed for bonding woven and non-woven materials, mineral wool, concrete, ceramics, wood and metal (except aluminum).

FiberMatrix is a non-flammable, water-based ceramic filler with endothermic effect, reinforced with short basalt fibers. The reinforcing fibers make it possible to use this putty to create 3D shapes for various non-combustible interior architectural elements. It has ultrahigh strength and excellent adhesion to woven and non-woven materials, mineral wool, concrete, ceramics, wood and metal (except aluminum). The material was successfully tested for non-combustibility according to FTP Code Part 1 (DIN EN ISO 1182) in the laboratory of CBG Composites GmbH. Due to its properties, FiberMatrix makes it possible to reduce the weight of 3D products and at the same time achieve high strength.

CBG fako® - Glass Fibre Adhesive 9119xtra is a solvent-free plastic dispersion adhesive, which is characterized by high elasticity. A one-component adhesive set thixotropic in nature. CBG fako® - glass fibre adhesive No. 9119 is used for the bonding of glass fibre fabric on mineral wool in pipe and surface area, and used to manufacture a glass cloth cover on rubber products (e.g. Armaflex). The adhesive can be used on stable substrates such as plaster, plasterboard and concrete.

Certificates & test reports:

- Certificate MED Module B

- Fire test report of an adhesive "fako® - Glass Fibre Adhesive 9119xtra" for surface flammability

- WIWEB approval (Bundeswehr Research Institute for Materials, Fuels and Lubricants)

FireStop is an inorganic, water-based impregnation for wood, concrete and fiber materials that penetrates deep into the pores of concrete, wood layers and the space between fibers, increasing fire and moisture resistance. It has a fungicidal effect (against mold and fungi). The advantage is that FireStop penetrates up to 8 mm deep. The fire protection class of wood goes up after impregnation to class B1 according to DIN 4102.

In addition, FireStop has endothermic effect (provides chemical cooling when heated) and is used to impregnate the cores of non-combustible sandwich panels. The company received a German Utility Model DE 20 20 20 103 298 U1 for using FireStop to impregnate non-combustible sandwich panel cores.

The company monitors developments in this area and develops new products that meet the needs of the market and customers.

2. The use of basalt and its derivatives as a base material in innovative composite technologies.

Why use Basalt in composites?

A composite consists of two components: fiber plus matrix (at least).

Fire resistance and strength. According to DIN EN ISO 1182, both components of refractory composites must not be combustible. Basalt fiber is great for this, because of high melting point (1400 оC) and chemical resistance. To compare, the melting temperature of E-glass is only 660 оC. With basalt you also get higher strength and adhesive properties, of course.

A composite consists of two components: fiber plus matrix (at least).

Fire resistance and strength. According to DIN EN ISO 1182, both components of refractory composites must not be combustible. Basalt fiber is great for this, because of high melting point (1400 оC) and chemical resistance. To compare, the melting temperature of E-glass is only 660 оC. With basalt you also get higher strength and adhesive properties, of course.

Recyclability. Basalt fiber is a 100% natural product and does not contain any chemical synthesis products, which is important for the environmentally sound use of the product and its disposal.

Selection.

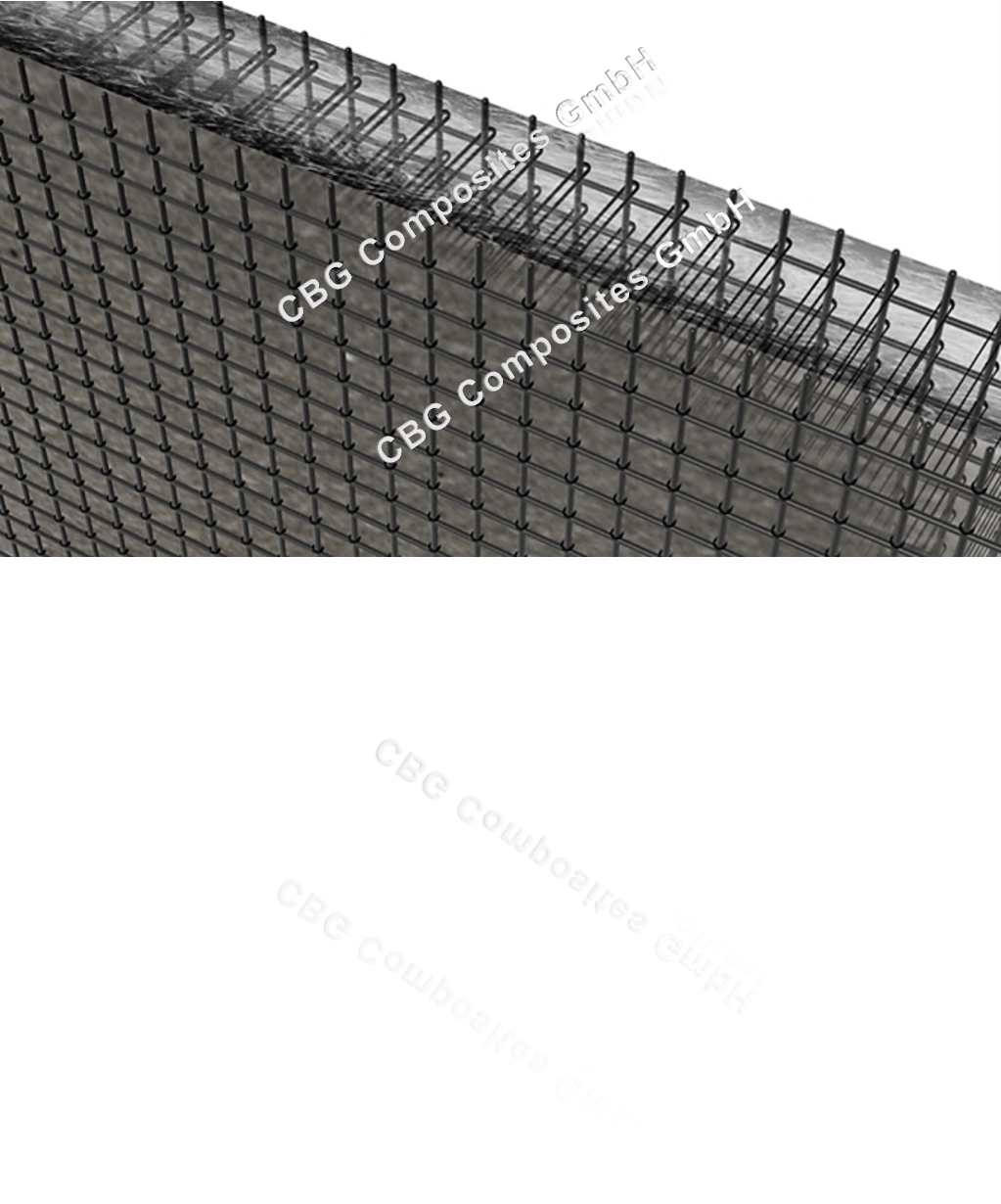

CBG Composites GmbH develops special woven and non-woven materials, fleece and mesh. [product link]

In addition, our subsidiary produces the highest quality basalt roving from 600 to 9600 tex using patented technology.

We also produce short-cut fibers in various lengths (from 6 to 72 mm) for spatial reinforcements and fillers for other applications.

Finally, in fire resistant composites one needs good adhesion between the fibers and the non-combustible matrix. So we developed a series of special lubricants that are optimally suited for the contact of the basalt fibers with the non-combustible matrix and impregnations.

1. Fire test report of a basalt fabric "CBG - LtBC-480.001" to determine non-combustibility.

2. Example of spatial reinforcement. Tensile test on a non-combustible basalt fiber composite.

If you are looking for fibers, please take a look here:

Product catalog: Basalt fiber LifeRock

If none of the product examples above fits perfectly, we can often customize or adjust, please let us know.

The areas of application of basalt fibers and composite materials made from basalt fibers are constantly expanding. So far we see them used in building construction, road construction, landscaping and shipbuilding.

Selection.

CBG Composites GmbH develops special woven and non-woven materials, fleece and mesh. [product link]

In addition, our subsidiary produces the highest quality basalt roving from 600 to 9600 tex using patented technology.

We also produce short-cut fibers in various lengths (from 6 to 72 mm) for spatial reinforcements and fillers for other applications.

Finally, in fire resistant composites one needs good adhesion between the fibers and the non-combustible matrix. So we developed a series of special lubricants that are optimally suited for the contact of the basalt fibers with the non-combustible matrix and impregnations.

1. Fire test report of a basalt fabric "CBG - LtBC-480.001" to determine non-combustibility.

2. Example of spatial reinforcement. Tensile test on a non-combustible basalt fiber composite.

If you are looking for fibers, please take a look here:

Product catalog: Basalt fiber LifeRock

If none of the product examples above fits perfectly, we can often customize or adjust, please let us know.

The areas of application of basalt fibers and composite materials made from basalt fibers are constantly expanding. So far we see them used in building construction, road construction, landscaping and shipbuilding.

3. Soundproofing with non-combustible composites.

Most soundproofing materials on the market are flammable.

Plus, for best noise protection you normally need thick structures or multiple layers of sound-reflecting and sound-absorbing materials.

So, CBG Composites developed lightweight soundproofing materials, which meet class A1 from DIN 4102, DIN 13501-1, DIN EN ISO 1182 (non-combustibility class A1 means that a soundproofing material does not burn when exposed to fire or temperatures of 750 OC, does not release harmful gases and remains dimensionally stable).

CBG panels effectively protect against 1) airborne noise, 2) structure-borne noise and 3) acoustic noise.

1) For effective airborne sound insulation, we offer solutions:

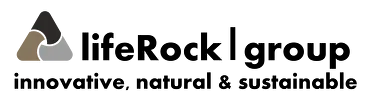

CBG EasyPan® (wall systems)

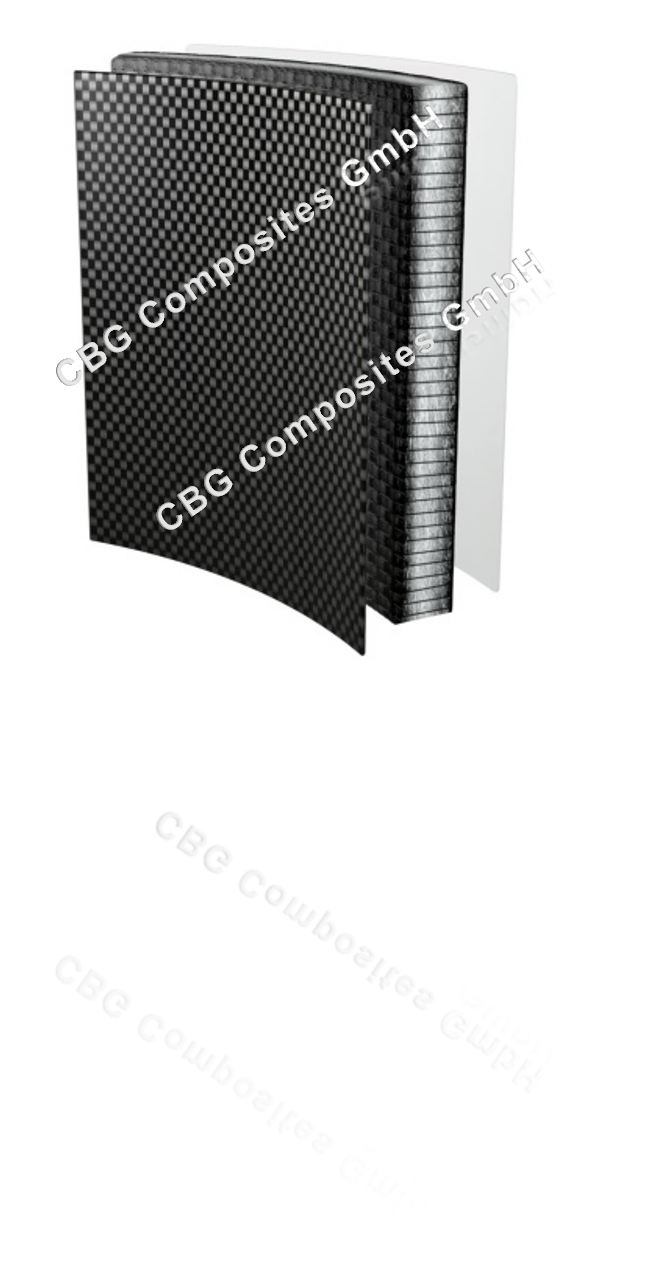

CBG EasyPan® pre-assembled acoustic wall panel system consists of two multi-layer panels with an open-pored structure on the inner surfaces, between which there is an air gap. The outer layers are made of solid basalt ceramic laminate. And inside each panel is an inner basalt fiber core. Such layers differ both in density and structure, which makes EasyPan very effective at soundproofing.

Most soundproofing materials on the market are flammable.

Plus, for best noise protection you normally need thick structures or multiple layers of sound-reflecting and sound-absorbing materials.

So, CBG Composites developed lightweight soundproofing materials, which meet class A1 from DIN 4102, DIN 13501-1, DIN EN ISO 1182 (non-combustibility class A1 means that a soundproofing material does not burn when exposed to fire or temperatures of 750 OC, does not release harmful gases and remains dimensionally stable).

CBG panels effectively protect against 1) airborne noise, 2) structure-borne noise and 3) acoustic noise.

1) For effective airborne sound insulation, we offer solutions:

CBG EasyPan® (wall systems)

CBG EasyPan® pre-assembled acoustic wall panel system consists of two multi-layer panels with an open-pored structure on the inner surfaces, between which there is an air gap. The outer layers are made of solid basalt ceramic laminate. And inside each panel is an inner basalt fiber core. Such layers differ both in density and structure, which makes EasyPan very effective at soundproofing.

Also, CBG EasyPan®-100 is already pre-assembled, so it does not need to be installed on a stud frame structure, there is no need for subsequent planking, and no sealing with sound-insulating mineral wool. Instead, you just need to install them on site. Significant reduction in time and labor, compared to building partitions with individual profiles and panels.

EasyPan is characterized by its low weight - 16.5 kg/m2.

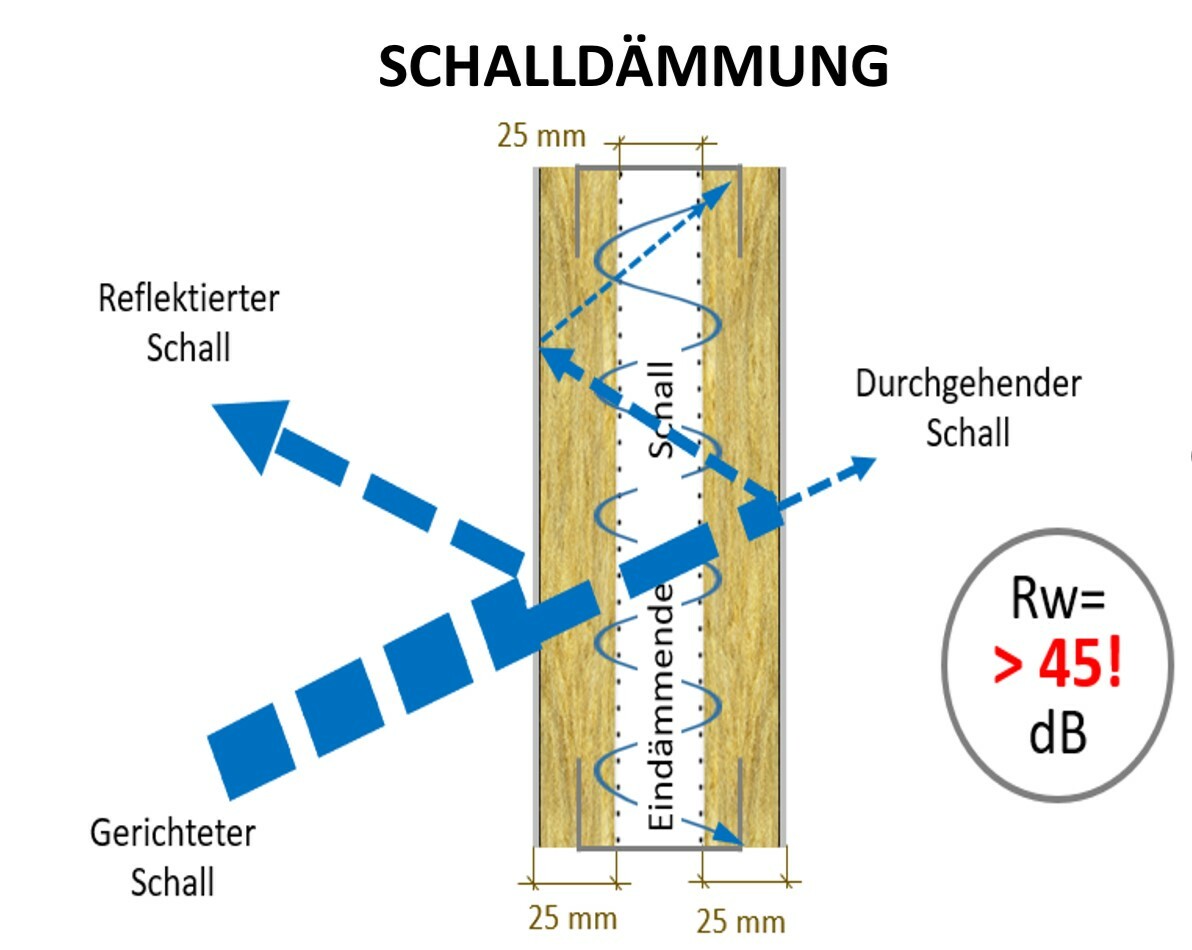

CBG SeaPan® FF (floor systems)

For sound insulation of false ceilings, the floating floor technology is very well known. This multi-layered construction is made of materials of different densities and resembles a puff pastry cake. A distinctive feature of the floating floor is that there is no fixed connection between the floor and the false ceiling. This ensures an independent position of the system, which significantly improves the soundproofing of a room.

For sound insulation of false ceilings, the floating floor technology is very well known. This multi-layered construction is made of materials of different densities and resembles a puff pastry cake. A distinctive feature of the floating floor is that there is no fixed connection between the floor and the false ceiling. This ensures an independent position of the system, which significantly improves the soundproofing of a room.

CBG Composites GmbH has developed and manufactures new non-combustible sound insulation panels SeaPan® FF-30/60. Unlike traditional panels, these panels have at least three layers of hard basalt ceramic laminate, with at least two porous basalt fiber cores in between. Each layer has its own position and function; together they form a fireproof acoustic system – the CBG floating floor system.

2) For effective sound insulation against structure-borne noise, see LifeRock MW-180, our sound-insulating basalt fiber sealing material.

3) For effective sound insulation against acoustic noise, we offer FirePan® 25/G (picture 1, picture 2) acoustic panels, which can be used for making acoustic screens.

See the panels in action:

Measurement of the airborne sound insulation of SeaPan WP 28G

Measurement of the airborne sound insulation of SeaPan WP 25G

Measurement of the airborne sound insulation of SeaPan WP 15G

3) For effective sound insulation against acoustic noise, we offer FirePan® 25/G (picture 1, picture 2) acoustic panels, which can be used for making acoustic screens.

See the panels in action:

Measurement of the airborne sound insulation of SeaPan WP 28G

Measurement of the airborne sound insulation of SeaPan WP 25G

Measurement of the airborne sound insulation of SeaPan WP 15G

4. Shipbuilding: non-combustible ultra-light materials.

Steel is of course the main structural material in shipbuilding, but it is four times heavier than traditional composites!

Traditional composites are mostly combustible, and so their use in shipbuilding is mostly restricted.

For passenger ships especially, the weight of a structure plays a special role. With lightweight materials, the weight of a ship can be reduced, which increases speed, reduces fuel consumption and reduces the emission of pollutants.

Our solution is to replace heavy steel structures with non-combustible, ultra-light composites wherever possible. Compared to traditional panels of a same fire-resistance class, these are generally half as thin and half as light.

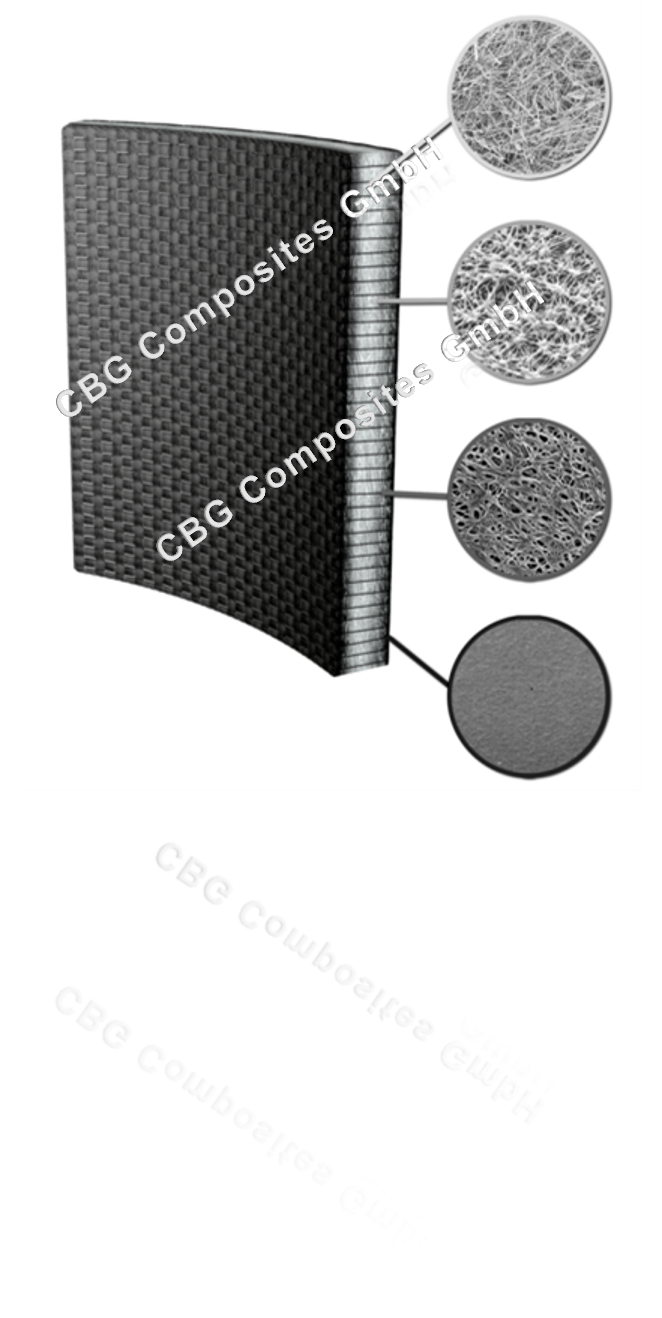

What's inside the composite material

Our composite material consists of:

The basalt fiber manufactured by our subsidiary (MeltRock®) has excellent strength properties and has a melting point of around 1400 oC. The non-combustible matrix LR Cerammatrix® 01-50 consists of inorganic, environmentally friendly components and is endothermic.

What's inside the fire-resistant sandwich panels

For the production of sandwich panels we use a LifeRock MW-180 mineral wool core, the fibers of which are specially aligned to achieve optimal strength and low weight.

The design of sandwich panels from these materials makes it possible to obtain ultra-light, strong, fire-resistant barriers of a given class (B-0, B-15, A-30, A-60). Compared to traditional panels of a same fire-resistance class, these are generally half as thin and half as light.

Learn more about the materials:

Basalt ceramic laminate LTBC 480, glass ceramic laminate LTGC 300, LTGC 200, matrices LR Cerammatrix® 01-50 and Cerammatrix Carbo, non-flammable mineral wool cores LifeRock MW-180, non-flammable mineral wool seals 12, 23, 37, 47mm.

Learn more about the panels and how they were certified:

SeaPan® WP 50/60 fire class A-60, SeaPan® FF 30/60 fire class A-60, SeaPan® WP 25/15 fire class A-30, SeaPan® WP 25/G fire class B-15. These panels are used as wall, floor and ceiling panels.

Certificates:

1) Module B: SeaPan® WP 25/15, SeaPan® WP 50/60, SeaPan® WP 25/G, LifeRock MW-180, CBG - LR Cerammatrix® 01-50.

2) Fire test reports to determine non-combustibility:: CBG - LtBC.480, CBG - LtGC.300, CBG - LtGC.200, CBG - LR Cerammatrix® 01-50, CBG - Cerammatrix-Carbo, LifeRock MW-180, SeaPan® WP 15/G.

The use of these products in shipbuilding offers advantages in terms of ship weight, reduced wall thickness and space requirements, increased ship efficiency and reduced construction costs. The prospects for further research in this area are clear to us and we are working on them. We are also happy to develop a material tailored to the individual needs of your project.

Steel is of course the main structural material in shipbuilding, but it is four times heavier than traditional composites!

Traditional composites are mostly combustible, and so their use in shipbuilding is mostly restricted.

For passenger ships especially, the weight of a structure plays a special role. With lightweight materials, the weight of a ship can be reduced, which increases speed, reduces fuel consumption and reduces the emission of pollutants.

Our solution is to replace heavy steel structures with non-combustible, ultra-light composites wherever possible. Compared to traditional panels of a same fire-resistance class, these are generally half as thin and half as light.

What's inside the composite material

Our composite material consists of:

- high-temperature-resistant basalt fibers

- and a non-combustible ceramic matrix

The basalt fiber manufactured by our subsidiary (MeltRock®) has excellent strength properties and has a melting point of around 1400 oC. The non-combustible matrix LR Cerammatrix® 01-50 consists of inorganic, environmentally friendly components and is endothermic.

What's inside the fire-resistant sandwich panels

For the production of sandwich panels we use a LifeRock MW-180 mineral wool core, the fibers of which are specially aligned to achieve optimal strength and low weight.

The design of sandwich panels from these materials makes it possible to obtain ultra-light, strong, fire-resistant barriers of a given class (B-0, B-15, A-30, A-60). Compared to traditional panels of a same fire-resistance class, these are generally half as thin and half as light.

Learn more about the materials:

Basalt ceramic laminate LTBC 480, glass ceramic laminate LTGC 300, LTGC 200, matrices LR Cerammatrix® 01-50 and Cerammatrix Carbo, non-flammable mineral wool cores LifeRock MW-180, non-flammable mineral wool seals 12, 23, 37, 47mm.

Learn more about the panels and how they were certified:

SeaPan® WP 50/60 fire class A-60, SeaPan® FF 30/60 fire class A-60, SeaPan® WP 25/15 fire class A-30, SeaPan® WP 25/G fire class B-15. These panels are used as wall, floor and ceiling panels.

Certificates:

1) Module B: SeaPan® WP 25/15, SeaPan® WP 50/60, SeaPan® WP 25/G, LifeRock MW-180, CBG - LR Cerammatrix® 01-50.

2) Fire test reports to determine non-combustibility:: CBG - LtBC.480, CBG - LtGC.300, CBG - LtGC.200, CBG - LR Cerammatrix® 01-50, CBG - Cerammatrix-Carbo, LifeRock MW-180, SeaPan® WP 15/G.

The use of these products in shipbuilding offers advantages in terms of ship weight, reduced wall thickness and space requirements, increased ship efficiency and reduced construction costs. The prospects for further research in this area are clear to us and we are working on them. We are also happy to develop a material tailored to the individual needs of your project.

5. Non-combustible ultra-light materials and their application in architecture and construction.

Traditional construction technology, especially in the area of dry construction, has hardly changed in recent decades.

In addition to the total cost, the speed of construction starts to play a special role these days. It also is becoming increasingly important to keep labor costs in control. Fire protection issue has always been relevant. In addition, the legal requirements for fire protection constructions and materials keep increasing, to protect the health and safety of people. Fire protection walls should preferably be built thin and light.

Our patented fire protection walls are based on basalt-ceramic composite laminates, which consist of basalt fibers and a ceramic matrix. The fire protection panels consist of a sandwich construction, for which a non-combustible LifeRock MW-180 multi-layer core was specially developed (Utility Model DE 20 2020 103 298).

Compared to traditional drywall solutions, our fireproof partitions are much lighter, quicker to assemble and have a reduced thickness for a given fire rating. This is achieved through special patented technical design solutions and through the unique properties of the following materials: the non-combustible adhesives LR Cerammatrix® 01-50 and Cerammatrix Carbo, the impregnated basalt fiber fabrics and nets, the patented, non-combustible sandwich core LifeRock MW-180.

The result these is known as CBG EasyPan®-100 quick-erect partition wall system for the rapid construction of fire-resistant, non-load-bearing interior walls (fire resistance class F-90). The technology of achieving lighter weight and thinner thickness has been adopted from the technology we use in marine panels. The result: reduced weight and thickness, plus less manual work to install.

Learn more about the CBG EasyPan®-100 quick-erect partition wall system and assembly instructions https://en.cbg-composites.de/products-and-services/easypan-100-system.

Utility Model:

1) DE 20 2018 106 673 "Fire-resistant multi-layer panel"

2) DE 20 2019 102 808 "Multilayer panel"

3) DE 20 2020 103 298 "Thermal insulating core for multi-layer panel"

4) DE 20 2021 105 205 "Building board"

Fire test reports:

FirePan 40/90

CBG EasyPan® - 100

Traditional construction technology, especially in the area of dry construction, has hardly changed in recent decades.

In addition to the total cost, the speed of construction starts to play a special role these days. It also is becoming increasingly important to keep labor costs in control. Fire protection issue has always been relevant. In addition, the legal requirements for fire protection constructions and materials keep increasing, to protect the health and safety of people. Fire protection walls should preferably be built thin and light.

Our patented fire protection walls are based on basalt-ceramic composite laminates, which consist of basalt fibers and a ceramic matrix. The fire protection panels consist of a sandwich construction, for which a non-combustible LifeRock MW-180 multi-layer core was specially developed (Utility Model DE 20 2020 103 298).

Compared to traditional drywall solutions, our fireproof partitions are much lighter, quicker to assemble and have a reduced thickness for a given fire rating. This is achieved through special patented technical design solutions and through the unique properties of the following materials: the non-combustible adhesives LR Cerammatrix® 01-50 and Cerammatrix Carbo, the impregnated basalt fiber fabrics and nets, the patented, non-combustible sandwich core LifeRock MW-180.

The result these is known as CBG EasyPan®-100 quick-erect partition wall system for the rapid construction of fire-resistant, non-load-bearing interior walls (fire resistance class F-90). The technology of achieving lighter weight and thinner thickness has been adopted from the technology we use in marine panels. The result: reduced weight and thickness, plus less manual work to install.

Learn more about the CBG EasyPan®-100 quick-erect partition wall system and assembly instructions https://en.cbg-composites.de/products-and-services/easypan-100-system.

Utility Model:

1) DE 20 2018 106 673 "Fire-resistant multi-layer panel"

2) DE 20 2019 102 808 "Multilayer panel"

3) DE 20 2020 103 298 "Thermal insulating core for multi-layer panel"

4) DE 20 2021 105 205 "Building board"

Fire test reports:

FirePan 40/90

CBG EasyPan® - 100

6. Additive technologies to produce high-temperature resistant products from biosoluble ceramic fibers.

Fire resistant composites and mineral fiber products are the most promising products in terms of strength and weight. In the EU there are strict requirements for the use of mineral fibers to protect human health and the environment. Mineral fibers include basalt and ceramic fibers. Mineral fibers that meet the requirements for biosolubility (RAL) usually have a lower temperature resistance than aluminosilicate fibers.

To increase the operating temperature of biosoluble fibers in products, CBG Composites GmbH has developed a technology that makes it possible to cover the biosoluble fibers with nanoscale layers of materials using an additive process, which have a higher temperature resistance than the biosoluble fibers themselves. In 2021, CBG Composites GmbH received a utility model specification no. 20 2021 105 451 for a utility model "Thermal insulating product made of ceramic fibers".

There is an urgent need for such fibers in metallurgy and power engineering to solve specific problems, and in the aerospace industry.

CBG Composites GmbH has developed a novel, very light heat shield tile for reusable civil spacecraft, the advantages of which are:

Areas of application: re-entry spacecraft; engine shielding for aircraft engines; hot gas turbine.

Fire resistant composites and mineral fiber products are the most promising products in terms of strength and weight. In the EU there are strict requirements for the use of mineral fibers to protect human health and the environment. Mineral fibers include basalt and ceramic fibers. Mineral fibers that meet the requirements for biosolubility (RAL) usually have a lower temperature resistance than aluminosilicate fibers.

To increase the operating temperature of biosoluble fibers in products, CBG Composites GmbH has developed a technology that makes it possible to cover the biosoluble fibers with nanoscale layers of materials using an additive process, which have a higher temperature resistance than the biosoluble fibers themselves. In 2021, CBG Composites GmbH received a utility model specification no. 20 2021 105 451 for a utility model "Thermal insulating product made of ceramic fibers".

There is an urgent need for such fibers in metallurgy and power engineering to solve specific problems, and in the aerospace industry.

CBG Composites GmbH has developed a novel, very light heat shield tile for reusable civil spacecraft, the advantages of which are:

- geometrically and thermally adaptive sandwich design;

- ultra light (< 0.5 g/cm³);

- highly thermo-mechanically resistant (> 30 min at 1,800 °C).

Areas of application: re-entry spacecraft; engine shielding for aircraft engines; hot gas turbine.

Material concept:

This development has enormous application potential for the future as mankind explores space more and more every year and a new thermal protection for reentry vehicles is required.

- Based on a 3D textile framework of ceramic additive fibres, a multilayer sandwich structure with load-bearing layers on the "hot" and "cold" side of the tiles is created

- "Hot" (outdoor) side: ceramic sandwich structure, "ceramic" glaze on the outside ("impact resistant" SiC) on a SiO2/SiC coated carbon fibre fabric with an inorganic matrix

- Sandwich core made of layered additized ceramic fibers of different densities, with multiple protective coatings of nanoscale SiO2 and SiC and/or other materials

- "Cold (back) side in fabric made of carbon and/or mineral fibre, also impregnated

- Support structure made of carbon fibres, EBC protection (environmental barrier coating) through e.g. Multilayer SiO2/SiC layers

This development has enormous application potential for the future as mankind explores space more and more every year and a new thermal protection for reentry vehicles is required.

7. Phenolic free inorganic binder CBG Ceramant 07-04 for production of mineral fibre thermal insulation materials.

CBG Ceramant 07-04 binder is a milky coloured liquid consisting of water soluble, non combustible organosilicon liquids and aqueous solutions mineral salts and is free from phenolic groups and radicals as well as other hazardous chemical compounds.

CBG Ceramant 07 04 should be diluted with water to the required concentration and fed into the process chain instead of phenolic binders in a similar way to phenolic binders, i.e. into the forming chamber through nozzles positioned on the centrifuge roll. CBG Ceramant 07 04 adheres well to mineral fibres and provides bonding of the fibres. It has a neutral hydrogen bonding index. After drying, the binder has a certain elasticity, which makes mineral wool product flexible. CBG Ceramant 07 04 binder has also proven itself well in vacuum forming technology. More information about CBG Ceramant 07- 04 can be found in the presentation "Phenolic free inorganic binder "CBG Ceramant 07-04" for production of mineral fibre thermal insulation materials".

Notification of receipt of utility model application.

Utility model registration certificate Nr. 20 2022 102 705.

CBG Ceramant 07-04 binder is a milky coloured liquid consisting of water soluble, non combustible organosilicon liquids and aqueous solutions mineral salts and is free from phenolic groups and radicals as well as other hazardous chemical compounds.

CBG Ceramant 07 04 should be diluted with water to the required concentration and fed into the process chain instead of phenolic binders in a similar way to phenolic binders, i.e. into the forming chamber through nozzles positioned on the centrifuge roll. CBG Ceramant 07 04 adheres well to mineral fibres and provides bonding of the fibres. It has a neutral hydrogen bonding index. After drying, the binder has a certain elasticity, which makes mineral wool product flexible. CBG Ceramant 07 04 binder has also proven itself well in vacuum forming technology. More information about CBG Ceramant 07- 04 can be found in the presentation "Phenolic free inorganic binder "CBG Ceramant 07-04" for production of mineral fibre thermal insulation materials".

Notification of receipt of utility model application.

Utility model registration certificate Nr. 20 2022 102 705.