Request a callback

Please give us your contact details and we will call you back

By clicking the Submit button I confirm my consent to the privacy Policy and agree to the processing of my personal data

Manufacturing of sandwich panels

Manufacturing of sandwich panels

The CBG Composites plant has the modern continuous processing line for production of sandwich-panels, high temperature barriers and fire-resistant panels made of incombustible composite laminate and fireproof calibrated mineral-cotton core with a capacity of 115 000 m2 sandwich-panels a year.

CBG Composites continuous processing line consists of the machines, organized in functional areas, which have a unified system of process data management. The line includes the complete production cycle. All processes are automated, and operation is provided from the control unit. Fast changeover for another sandwich-panel type is possible.

Sandwich-panels: SeaPan, CCP, CB-Pan, CBG UP are entirely high-tech products. Deflections or elimination of separate links in the processor chain are inadmissible.

Line Technical Specifications:

CBG Composites continuous processing line consists of the machines, organized in functional areas, which have a unified system of process data management. The line includes the complete production cycle. All processes are automated, and operation is provided from the control unit. Fast changeover for another sandwich-panel type is possible.

Sandwich-panels: SeaPan, CCP, CB-Pan, CBG UP are entirely high-tech products. Deflections or elimination of separate links in the processor chain are inadmissible.

Line Technical Specifications:

- Line speed: min. - 1.0 m/min, max. - 6 m/min;

- Line dimensions: length 40 m, width 3.5 m, height 3 m;

- Required production area, min: 7 m x 50 m;

- Temperature environment: 15-25°С

- Compressed air: 6 atm, filtered, dry;

- Voltage: 380 V, 3 phase;

- Total power consumption: 85 kW

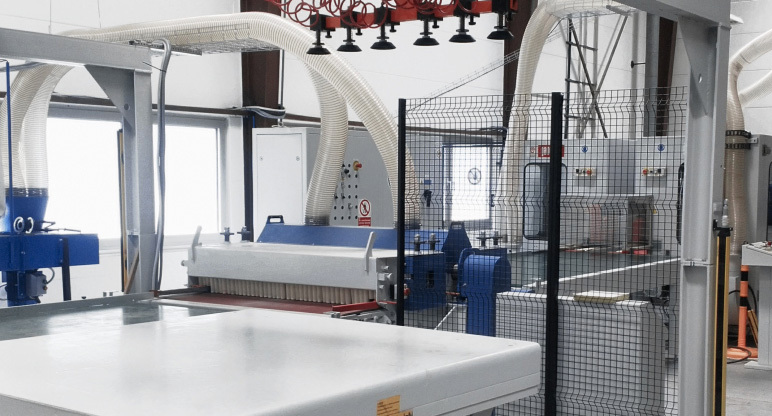

Cutting, milling and trimming

Cutting, milling and trimming

The CBG Composites plant has the modern processing line for cutting of basalt-ceramic-sandwich-panels to suit individual customer dimensions with a capacity of 115 000m2 sandwich-panels a year. The line also allows to trim and mill panel ends for every profile.

CBG Composites continuous processing line consists of the machines, organized in functional areas, which have a unified system of process data management. The line includes the complete production cycle. All processes are automated, and operation is provided from the control unit.

Line and Product Technical Specifications:

CBG Composites continuous processing line consists of the machines, organized in functional areas, which have a unified system of process data management. The line includes the complete production cycle. All processes are automated, and operation is provided from the control unit.

Line and Product Technical Specifications:

- Line speed: min. - 1.0 m/min, max. - 6 m/min;

- Line dimensions: length 15 m, width 5 m, height 3.5 m;

- Required production area, min: 9 m x 18 m;

- Temperature environment: 15-25°С

- Compressed air: 6 atm, filtered, dry;

- Voltage: 380 V, 3 phase;

- Total power consumption: 45 kW

- Product width: min: 350 mm, max: 2000 mm

- Product length: min: 1500 mm, max: 3500 mm

- Product height: min: 15 mm, max: 50 mm

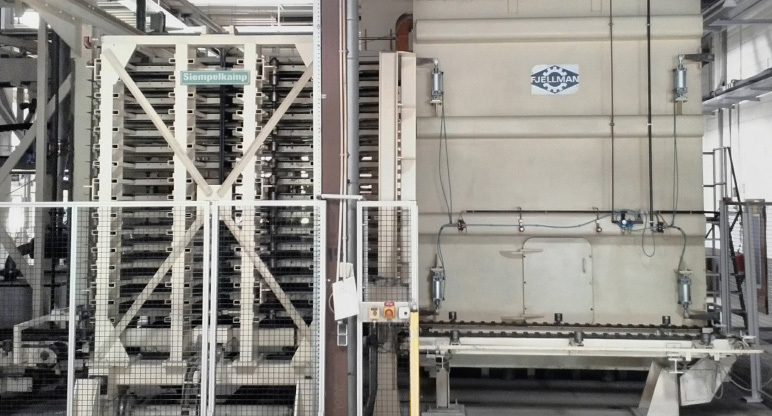

Pressing of laminates and sheets

Pressing of laminates and sheets

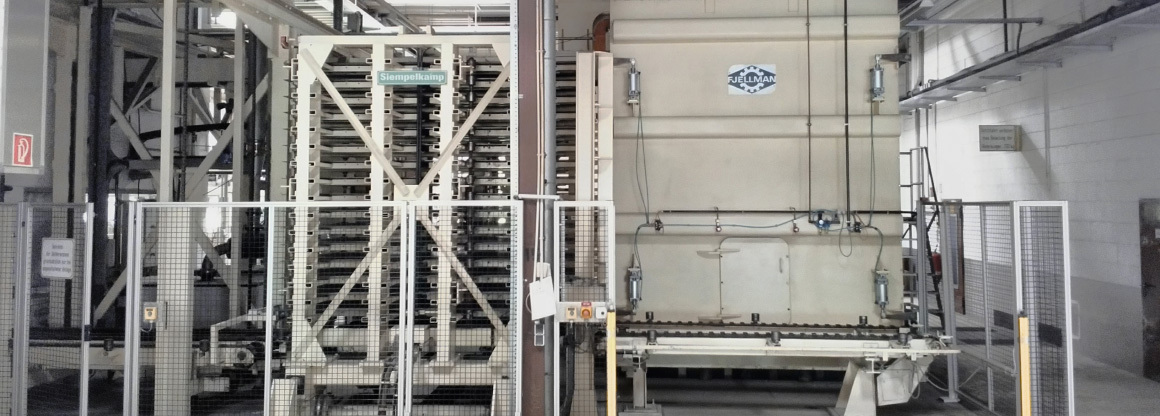

CBG Composites factory has modern stationary 16-level press, used for producing composite panel and sandwich-panels. The press work's with various materials, such as: epoxy or phenol, carbon, basalt, glass, polyethylene, etc..

In addition to the standard panels, smaller panels are also available, custom made.

Specifications:

In addition to the standard panels, smaller panels are also available, custom made.

Specifications:

- Press format 1270 x 2615 mm

- Plate thickness: min. 0,05mm max. 40 mm

- maximal force 3000 t

- maximal temperature 195°C