Request a callback

Please give us your contact details and we will call you back

By clicking the Submit button I confirm my consent to the privacy Policy and agree to the processing of my personal data

Shipbuilding and Offshore

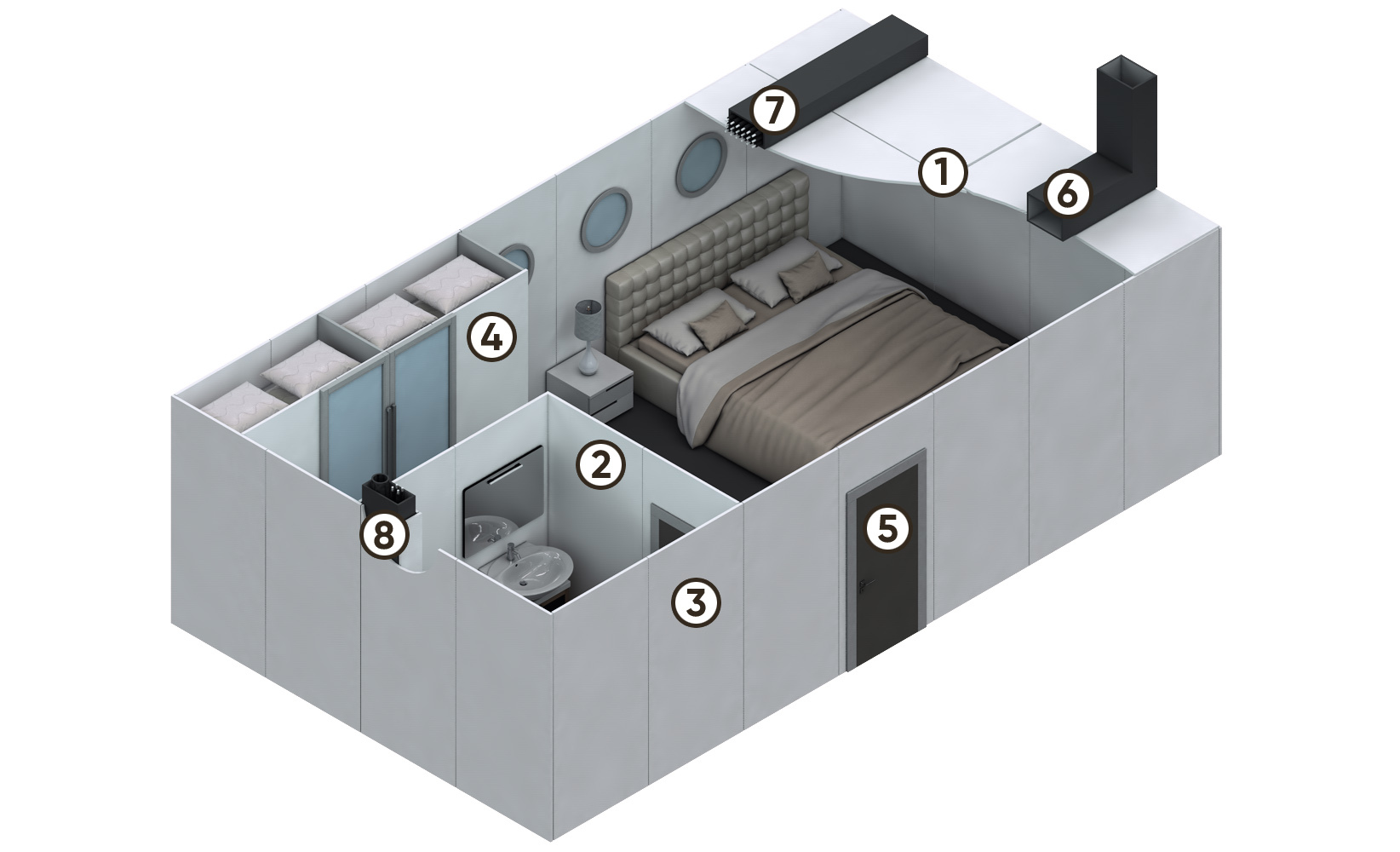

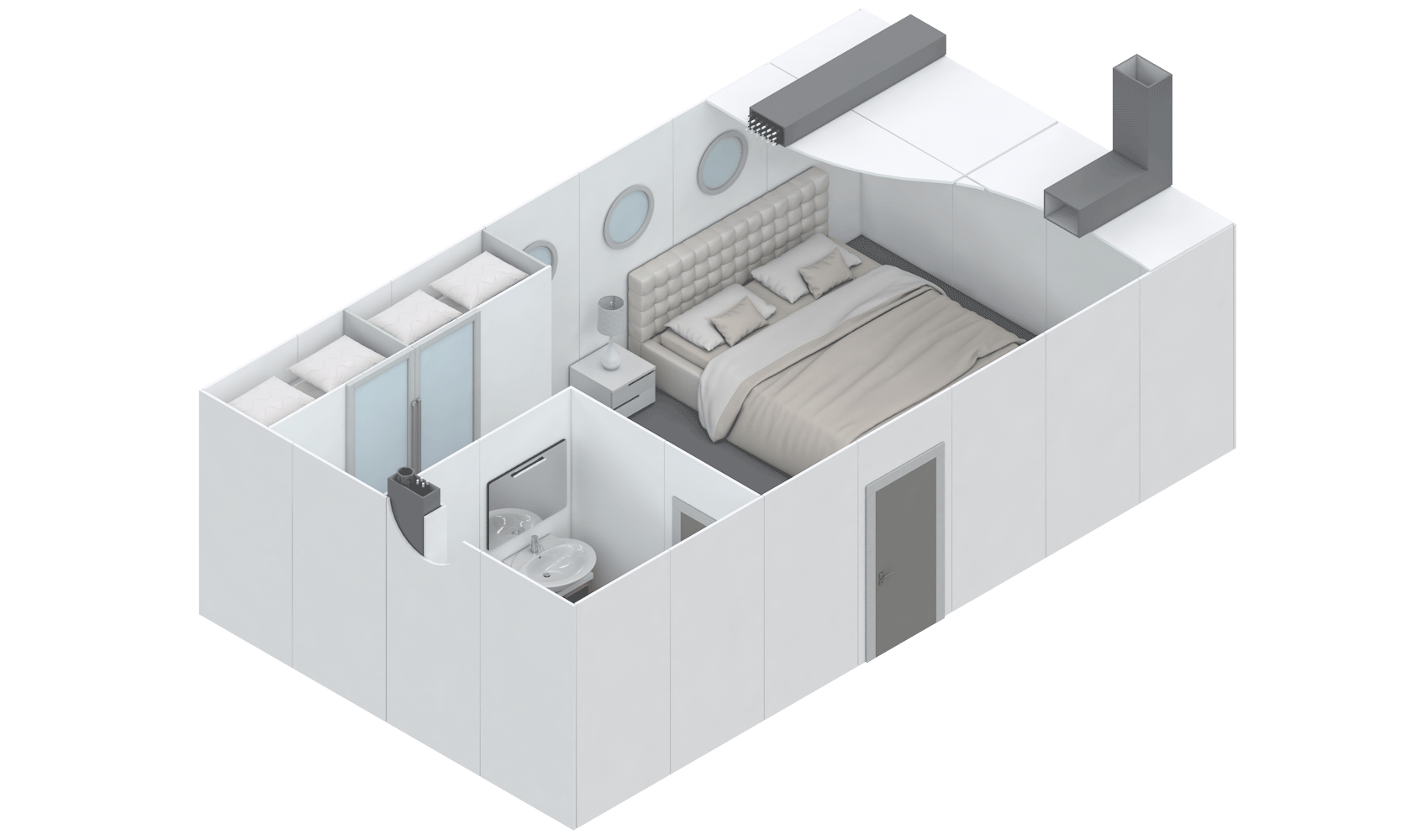

One of the most important and promising uses of our products is use as materials for the production of fire-resistant, heat- and noise-insulating structures for water use. Especially in those cases when the use of non-combustible materials is prescribed for their production: sea-going ships that travel more than 20 miles from the shore and receive more than 36 people on board, sea-going and river-going ships that require highly comfortable, noise-insulated cabins, offshore gas and oil production platforms, offshore electric power stations, residential and working sea containers, etc.

One of the most important and promising uses of our products is use as materials for the production of fire-resistant, heat- and noise-insulating structures for water use. Especially in those cases when the use of non-combustible materials is prescribed for their production: sea-going ships that travel more than 20 miles from the shore and receive more than 36 people on board, sea-going and river-going ships that require highly comfortable, noise-insulated cabins, offshore gas and oil production platforms, offshore electric power stations, residential and working sea containers, etc.

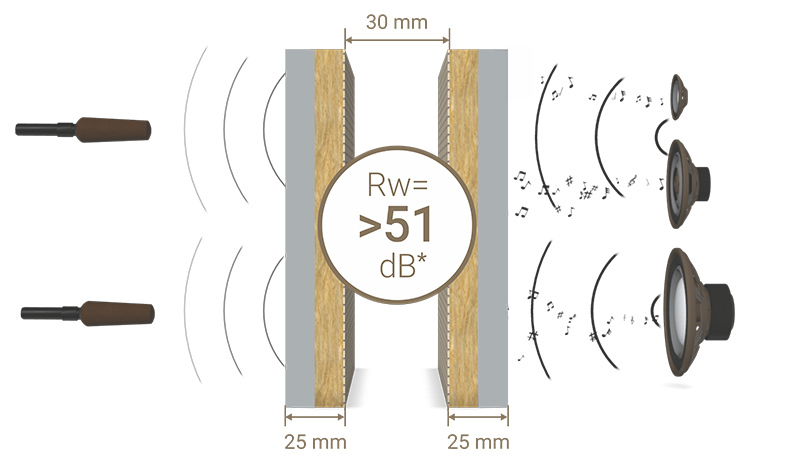

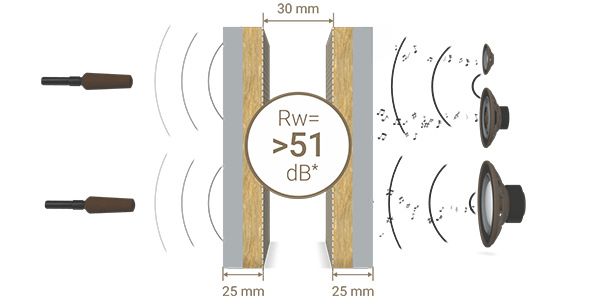

Our products make it possible to realize designs with specified fire resistance of B-0, B-15, B-30, B-60, B-90, B-120, etc. in accordance with IMO 2010 FTPC3. They can handle temperature loads of more than 1.100°C, are 100% made of natural materials, non-toxic, do not emit smoke in case of fire, waterproof, vibration and UV resistant, ultra-lightweight (specific density less than 780 kg/m³) and have unique soundproofing properties (> 51 dB) with a structural thickness of the partition less than 100 mm.

Our products make it possible to realize designs with specified fire resistance of B-0, B-15, B-30, B-60, B-90, B-120, etc. in accordance with IMO 2010 FTPC3. They can handle temperature loads of more than 1.100°C, are 100% made of natural materials, non-toxic, do not emit smoke in case of fire, waterproof, vibration and UV resistant, ultra-lightweight (specific density less than 780 kg/m³) and have unique soundproofing properties (> 51 dB) with a structural thickness of the partition less than 100 mm.

Fire-resistant, heat- and noise-proof, extremely lightweight, shape stable, easily machinable with conventional cutting tools and perfectly able to withstand mechanical loads CBG Composites GmbH products are perfectly suitable for the production of fire- and noise-proof enclosures for working machines as well as noise, heat- and fire-proof machine parts and various structures.

Fire-resistant, heat- and noise-proof, extremely lightweight, shape stable, easily machinable with conventional cutting tools and perfectly able to withstand mechanical loads CBG Composites GmbH products are perfectly suitable for the production of fire- and noise-proof enclosures for working machines as well as noise, heat- and fire-proof machine parts and various structures.

The system of coupling of panels "tongue-and-groove" developed and used by us in combination with their good mechanical and structural parameters allows to assemble the necessary constructions with the minimum effort on time and resources by use of conventional cutting tool.

Of course, in addition to the above connection of individual construction elements, our panels can also be mounted perpendicular to each other using screw connections and conventional standard fastening elements as floor, ceiling and corner elements and guide rails. In any case, we will be happy to help you choose the optimal solution.

If you do have any further questions, we are waiting for you to contact us. You will find our contact details on our website.

The system of coupling of panels "tongue-and-groove" developed and used by us in combination with their good mechanical and structural parameters allows to assemble the necessary constructions with the minimum effort on time and resources by use of conventional cutting tool.

Of course, in addition to the above connection of individual construction elements, our panels can also be mounted perpendicular to each other using screw connections and conventional standard fastening elements as floor, ceiling and corner elements and guide rails. In any case, we will be happy to help you choose the optimal solution.

If you do have any further questions, we are waiting for you to contact us. You will find our contact details on our website.

Of course, in addition to the above connection of individual construction elements, our panels can also be mounted perpendicular to each other using screw connections and conventional standard fastening elements as floor, ceiling and corner elements and guide rails. In any case, we will be happy to help you choose the optimal solution.

If you do have any further questions, we are waiting for you to contact us. You will find our contact details on our website.